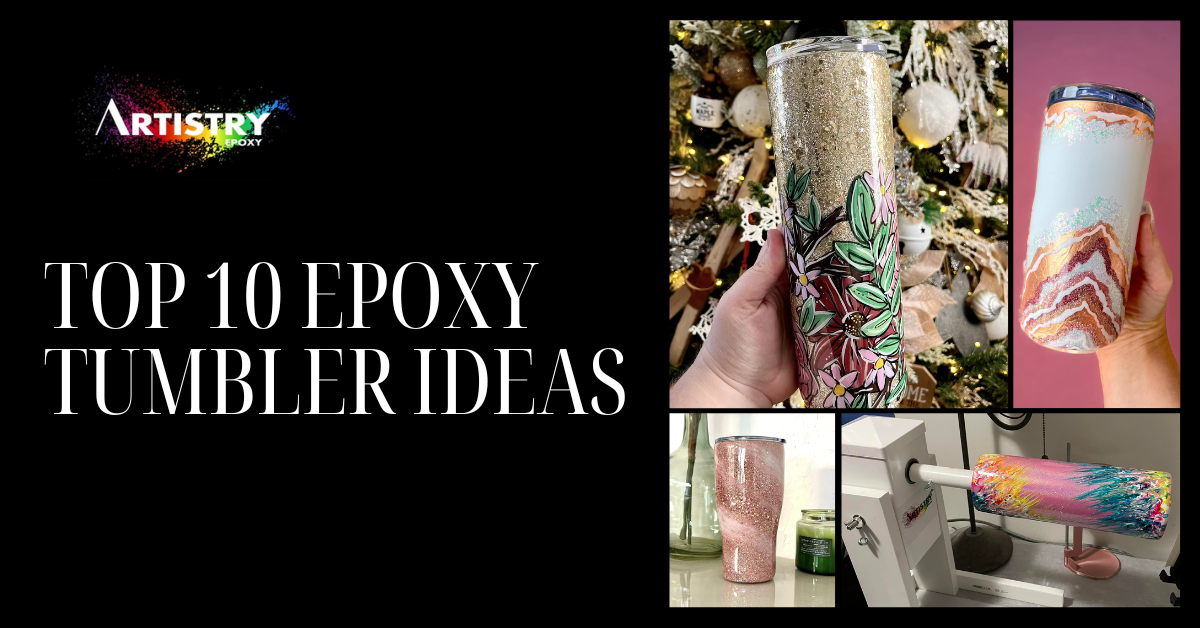

Creating Stunning Epoxy Resin Turning Projects!

Creating Stunning Epoxy Resin Projects: A Comprehensive Guide for Creators

Epoxy resin is a versatile and fascinating medium that opens up a world of creative possibilities, from jewelry to crafts. In this comprehensive guide, we’ll delve deep into the art of epoxy turning, a technique that allows you to craft beautiful items such as pens, wine stoppers, holiday decorations, bowls, and even toys.

Supplies You’ll Need

Before you embark on your epoxy turning journey, gather the following supplies:

– measuring cups

– Casting molds (silicone, hard plastic, or DIY molds)

– Infrared thermometer

– Plastic mixing cups

– Mica powder, glitter, Epoxy Pigments

– Stir sticks

– Mold release (optional)

– Rubber gloves/safety goggles

– Pressure pot (optional)

– Wood Turning machine and tools

Why Use a Pressure Pot?

A pressure pot is a great way for eliminating air bubbles in resin castings, ensuring a flawless finished product. If your pour exceeds a quarter inch in depth, a pressure pot is highly recommended. If you opt not to use one, mix your resin carefully to prevent introducing air bubbles.

Creating a Resin Blank: Step-by-Step

1. Mixing Resin and Hardener: Slowly pour resin into a mixing cup, followed by the hardener (usually in a 1:1 ratio, for deep pours most are 2:1). Stir the mixture thoroughly until it becomes clear, paying attention to the sides and bottom of the cup.

2. Adding Color: Once clear, . Add mica powder,Glitter, Color Pigments for color. For multicolored projects, separate the mixture into smaller cups and create various color mixtures.

3. Pouring into Molds: For single-colored items, pour the mixture after Step 2. For multicolored items, wait until the material reaches around 100 degrees Fahrenheit for proper color separation. Start with the base color and add accent colors. Use a mold release spray to prevent sticking.

4. Pressure Pot: If using a pressure pot, leave the blank inside for the full recommended resin cure time.

5. Demolding: After 24 to 72 hours of curing, remove the resin blank from the mold.

Resin Curing Times and Temperatures

Understanding the reaction between resin and hardener is crucial for successful epoxy turning. Here are some essential temperature and time guidelines:

Tips

– Open Time: This is the period before epoxy resin begins to gel and varies based on the resin type.

– Working Temperature: Maintain a workspace temperature of 75-80 degrees Fahrenheit for optimal results.

– Mixing Colors: After thorough mixing, add mica powder or dye to your resin. For swirling multiple colors, mix in smaller containers.

– Pouring: The ideal pouring temperature is around 75-80 degrees Fahrenheit.

Lathe Tips for Resin Turning

Turning epoxy resin requires careful consideration. Here are some tips to enhance your resin turning experience:

– Carbide Cutting Tools: Carbide cutters offer smooth cuts on hard materials like epoxy resin. They scrape the surface rather than cut, making them ideal for resin turning.

– Negative Rakes: Tools with negative rakes provide consistent cuts on epoxy resin, preventing melting and ensuring a smooth finish.

– Gentle Pressure: Avoid excessive pressure on the turning blank, as it can melt the resin. Start with light passes to smooth the surface.

– Starting Slowly: Begin with light passes at lower speeds to minimize chipping and blow-outs.

– Experimentation: Every project is unique. Experiment with lathe speeds, pressures, and tools until you find the perfect setup for your resin turning projects.

Turning Epoxy on a Wood Lathe: Step-by-Step Process

Turning epoxy on a wood lathe can be a rewarding and creative experience. Follow these step-by-step instructions to achieve smooth and polished results:

Step 1: Safety First

Before you start, ensure you are wearing appropriate safety gear, including safety goggles, a dust mask, and hearing protection.

Step 2: Prepare Your Lathe

Secure your epoxy resin blank onto the lathe using a chuck or other appropriate mounting method. Make sure the blank is tightly secured to prevent wobbling during the turning process.

Step 3: Select the Right Tools

Choose the appropriate cutting tools for epoxy turning. Carbide cutting tools are highly recommended as they provide clean cuts and reduce the risk of chipping or melting the resin. Ensure the tools are sharp and in good condition for optimal results.

Step 4: Start Turning

Begin by turning the lathe on at a low speed. Slowly bring the turning tools into contact with the rotating epoxy blank. It’s essential to start with light cuts to avoid putting too much pressure on the material.

Step 5: Shape the Blank

Carefully shape the epoxy blank using the turning tools. Keep the tools moving smoothly across the surface to prevent uneven spots or gouges. Epoxy turns best at higher speeds compared to wood, so gradually increase the lathe speed as you work.

Step 6: Check the Progress

Frequently stop the lathe to inspect your work. Feel the surface of the epoxy blank with your hand to ensure it’s smooth and even. Make any necessary adjustments to the shape and continue turning.

Step 7: Finishing Touches

Once you’re satisfied with the shape, switch to finer-grit sandpaper to refine the surface further. Sand the epoxy blank while the lathe is running at low speed, moving through progressively finer grits until you achieve the desired smoothness.

Step 8: Polishing

After sanding, you can polish the epoxy surface to a high shine using polishing compounds or abrasive pastes specifically designed for resin materials. Apply the polish while the lathe is running at a low speed, using a soft cloth or felt pad.

Step 9: Final Inspection

Inspect the turned epoxy piece thoroughly to ensure there are no imperfections or rough spots. Make any final adjustments if necessary.

Step 10: Applying a Finish (Optional)

If desired, you can apply a clear epoxy resin finish to enhance the appearance of your turned piece. Follow the manufacturer’s instructions for the epoxy finish you’re using.

By following these steps and exercising patience and precision, you can achieve outstanding results when turning epoxy on a wood lathe. Remember, practice and experimentation will help you refine your skills and create stunning epoxy-turned projects.